By Samantha Kummerer, Bond LSC

What happens when a chemical engineer, a computer scientist, and an immunologist walk into a lab?

Vaccines are created faster and cheaper.

At least this trio hopes that’s the answer.

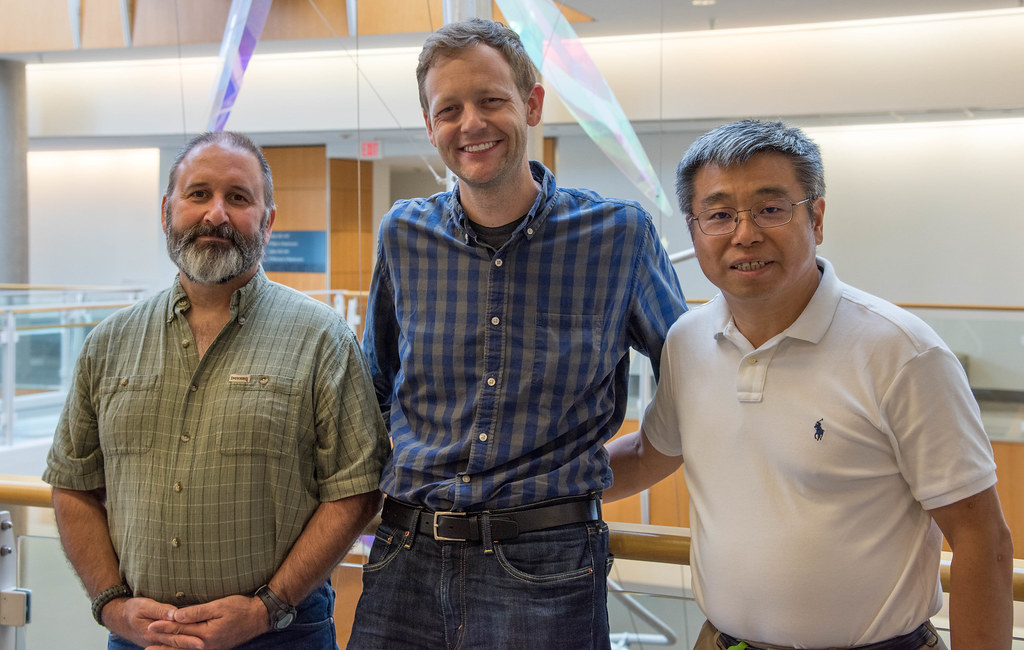

Bond Life Sciences Center computer scientist Dong Xu joined forces with immunologist Jeffery Adamovicz and chemical engineer Bret Ulery for the first time in February 2016. After 18 months and a $100,000 Bond Life Sciences startup grant, the team is closing in on a novel approach to vaccinations. They hope to start collecting initial data in the near future.

“Without this grant, it would be hard to work together,” Xu said. “Bond Life Sciences Center really played an important role for the collaboration research on campus and also for providing this seed money. They really foster these types of collaboration.”

The Problem

Efficiency has plagued the vaccination field for decades.

Traditionally, scientists create new vaccines by continuously guessing which components of the virus or bacteria to test.

“It was a plug-and-play type test system,” explained Adamovicz, who has researched vaccines for years. “We said, ‘well we could try this antigen or that antigen or that antigen and you would mix them together in different combinations and try them and then you would end up selecting one that would work.”

The process is similar to finding a needle in a haystack. It’s like scientists sort through and test every strand of hay until they discovered the needle.

As you can imagine, this method takes a long time to find something usable.

This process becomes a larger issue when viruses emerge that call for immediate measures, such as Zika or Ebola.

Creating vaccines can take a long time because sometimes a variety of different related bacteria cause illnesses. This makes that already inefficient guessing game more complicated by adding, even more, components to test.

Adamovicz explained scientists make a new vaccine each year by predicting which strain of the disease will infect the most people. This is why many people who get a flu vaccination can still get the flu — the strain they caught was not included in the vaccine.

The Solution

Xu, Ulery and Adamovicz decided to combine their strengths from their different fields to approach creating a vaccine in a new way to solve these two problems.

Adamovicz explained this type of collaboration is not routinely attempted when developing new vaccines.

Computer science and engineering enabled the team to more easily sort through thousands of potential options. Xu’s lab and his students created an algorithm to select candidates to test. Without Xu, the team would have to test tens of thousands of different antigen and peptide combinations. But with the algorithm, the team narrowed the combinations to about 10 to test.

Adamovicz said this method has the potential to create vaccines in half the normal time.

“I feel that it is a very meaningful work; that’s why I am interested in doing it because I do see the potential impact,” Xu said.

Putting a theory to work

Burkholderia is the first Guinea pig for their new approach.

The potentially deadly bacterial infection occurs in places like Thailand and northern Australia and is caused by a family of related bacteria called Burkholderia pseudomallei. But other strains of Burkholderia also cause disease in patients with Cystic Fibrosis across the globe.

“That was part of the challenge,” Adamovicz said. “It wasn’t that we could take a single bacterium and that’s all we had to worry about. We were worrying about a family of bacteria that had this variation in their genomic sequence and the proteins they produce.”

To eventually create a vaccine that could cure all strains of the bacteria, the team aimed to find a small piece of protein all Burkholderia had within their flagella, the whip-like structure of the bacteria that allows them to propel themselves.

To limit the number of segments within the protein, Adamovicz’s lab, on the biology side, determined some requirements for Xu to write an algorithm.

“It’s not to say this is like Star Trek where you just tell the computer and it does it on its own, it requires a lot of knowledgeable human input to spit out the answers,” said Adamovicz.

Adamovicz explained they wanted a vaccine that would trigger two immune responses. When harmful substances enter the body, like viruses or bacteria, the body responds in two ways. One way is through cellular immunity that responds by activating cells that already exist. The other way the body responds is by other cells making proteins called antibodies, which is called the humoral response.

The segment also had to be conservative, meaning it is less likely to mutate so there is a higher chance a vaccine would continue to be effective against the bacteria and would be effective against more members in the bacterial family. The last criteria Xu’s lab coded for ensured the protein is not similar to others found in humans.

All these limitations lowered more than three thousand possible candidates down to a testable amount and a final list of 10 candidates.

Then the research moves on to Ulery’s Lab. Here a team of chemical engineers take the identified candidates from Xu’s work and engineer targeted vaccine antigen nanoparticles termed micelles. These micelles are comprised of fat-based cores that display vaccine antigens on their surface and have been shown to induce strong immune responses.

“Most of them [subunit vaccines] are somewhat hydrophilic — water-liking peptides, portions of a protein — and we tether a fat to them and what happens is now you have something that likes water and something that doesn’t like water, and you throw it in water and they self-assemble into these small micelles,” Ulery said. “That clustering of all those peptide molecules together actually enhances the immune response to them.”

Then, the work goes back to Adamovicz to evaluate what the portions of proteins are going to make the best vaccine.

This cycle continues as all labs work to enhance and develop the design further.

“It’s a process that takes a village. It doesn’t necessarily take the whole village but you need the right people in the village to work together and that’s kind of what we’re doing,” Adamovicz explained. “We’re recognizing that there are areas in previous work that could have been better optimized.”

After months of back and forth, the team is preparing to feed infected cells some of the selected peptides, the small portions of protein. Those candidates that do well in the cell culture will be tested in mice exposed to the Burkholderia bacteria.

The team hopes this round of data collection will serve as a baseboard for future experiments. If this principle is proven in one antigen, a larger grant may enable the theory to be tested in hundreds of other antigens and applied to other diseases. Over the next four to six months, the team hopes to have a clearer vision for the future of this research.

The team credits the Bond LSC grant for bringing them together and for helping establish initial research to prove an approach like this could be impactful.

But, these types of collaborations don’t stop here.

“Previously, it was small stakeholders working on one protein their entire life, but that’s more basic research. To solve real-world problems requires many, many aspects, so the way that we are working in terms of interdisciplinary collaboration, I think that presents the future and this is already on-going in terms of an overall biology trend,” Xu explained.

Dr. Dong Xu is a professor in the University of Missouri’s Electrical Engineering and Computer Science Department and the Bond Life Sciences Center. His Digital Biology Lab develops and uses computers and software programs to help biological and medical researchers analyze large amounts of data.

Dr. Jeffrey Adamovicz is an associate professor in Veterinary Pathobiology and the director of the Laboratory of Infectious Disease Research. He works on developing vaccines and on animal models for zoonotic diseases.

Dr. Bret Ulery is an assistant professor in MU’s Chemical Engineering Department. He directs the Biomodulatory Materials Engineering Lab that creates new biomaterials for applications in immunology and regenerative medicine. He earned his doctorate degree from Iowa State University.